Research and development technology

Since its inception, the company has unwaveringly committed to crafting superior quality productsand championing operational excellence,evident in its robust portfolio of international accreditedcertifications;IS09001 (Quality Management),IS0 14001 (Environmental Sustainability),IS022000&BRC Global Standard (Food Safety Assurance).Kosher, Halal,USDA/EU Organic Certification,FDARegistrations and proprietary product patents.

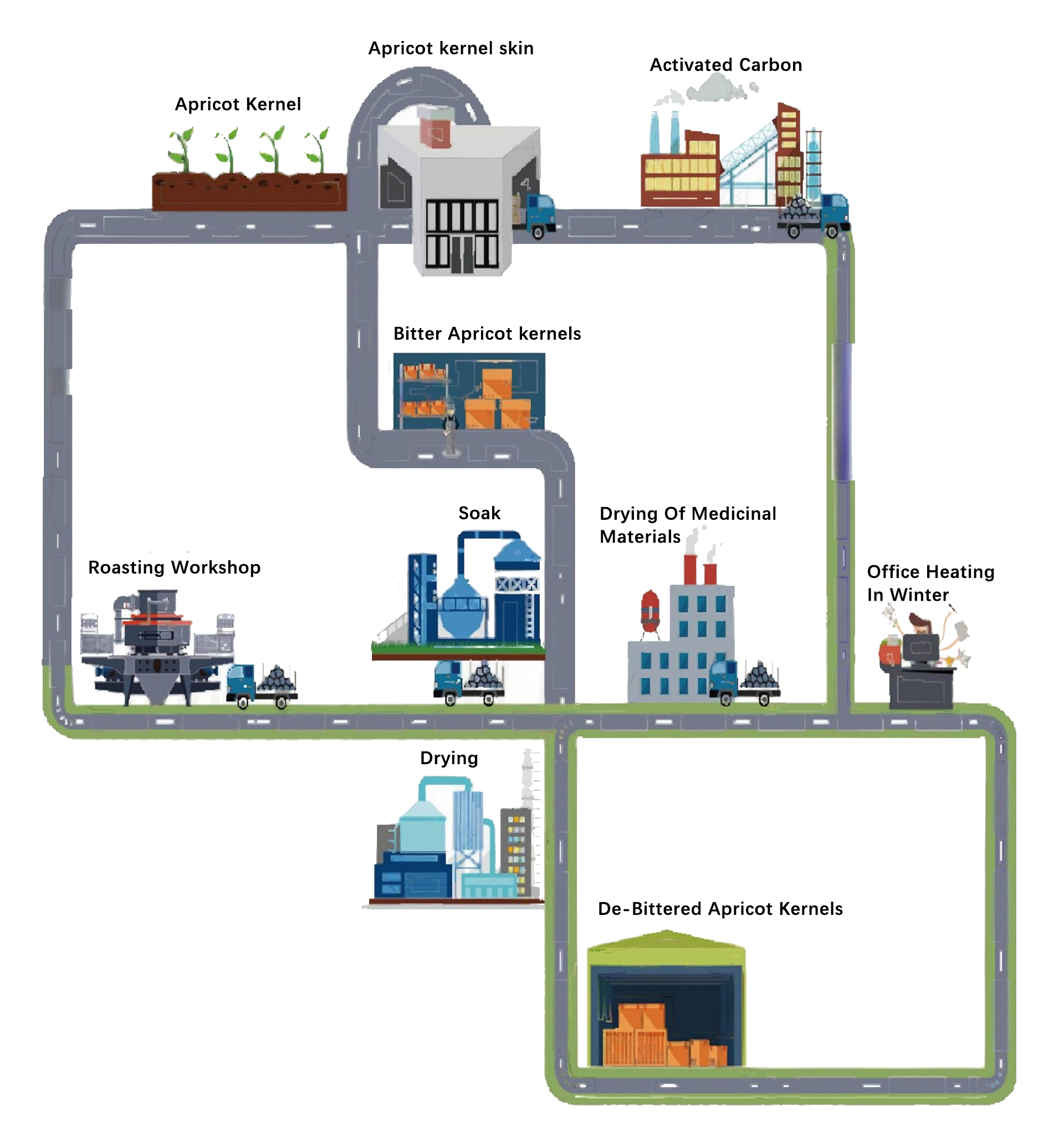

Plant Extraction, Separation, and Structural Modification Technologies

Extraction and separation are among the most important steps in the plant extraction process. The goal is to maximize the extraction of active ingredients from raw materials while removing toxic components. This technology is widely used in raw materials such as amygdalin and Rhodiola extract.

Plant Extract Component Activity Enhancement Technologies

Applying new technologies such as improved water solubility, molecular stability, and targeted release, to enhance the functionality and reduce the toxicity of plant extracts is a key technology for achieving differentiation in compound research products.

Plant Extract Component Safety Enhancement Technologies

This includes technologies for removing heavy metals, solvent residues, pesticide residues, and specific harmful components.

Plant Extract Component Functional Formulation Technologies

Functional compound research is the foundation of formula product development, providing strong technical support for the company’s OEM and ODM businesses and subsequent development of flagship products.

R&D TEAM

A Team Of Doctors And Experts Built This Technological Moat. Natural Field Has Focused On Nutritional Ingredients For 20 Years, Establishing A Research And Development And Technical Team Of 32 People, More Than 50% Of Whom Are Graduate Students, Doctors, And Postdoctoral Researchers. Natural Field Continuously Innovates And Develops New Products, Holding Nearly 100 Patents, And Provides High-Quality Raw Materials And Solutions To Numerous Global Nutrition And Health Companies.。

ADVANCED EQUIPMENT

The Factory Is Built In Strict Accordance With Gmp Standards, Utilizing Highly Automated, Intelligent, And Professional Modern Equipment To Ensure Fast And High-Quality Order Fulfillment.

RAW MATERIAL SELECTION

From Supplier Evaluation And Contract Signing To Raw Material Storage, We Follow International Standard Procurement Processes, Controlling Quality From The Source And Ensuring Comprehensive Inspection And Traceability.

CERTIFICATION

Thanks To Iso 22000 Certification, China Food Production License (Sc) 39+, National Patents, And Nearly 10 Domestic Authoritative Certifications And On-Site Verifications From Multiple Domestic And International Institutions, Natural Field’s Products Have Gained A Unique Status For Entering High-End Markets.

PRODUCTION ENVIRONMENT

The 10,000 And 100,000 Class Cleanrooms, Gmp-Compliant Processing Environment, And The Acquisition Of Wastewater Discharge Permits Provide The Most Reliable Guarantee For The Safety And Sustainability Of Our Production.

AUTHORITATIVE TESTING

Our Quality Control Center Is Equipped With Advanced Testing Equipment Such As Agilent Chromatography, Atomic Absorption, Infrared, And Ultraviolet Spectrometers, Reflecting Our Ultimate Commitment To Quality. Our Prestigious Cnas International Certification Has Earned Us Global Respect In The Field Of Quality Control.