A GMP-Compliant Amygdalin Manufacturer

In Amygdalin manufacturing, GMP is not just a documentation system—it represents a long-term commitment to production stability and risk control.

As a GMP-compliant Amygdalin manufacturer, we integrate GMP principles into raw material management, process control, and quality decision-making to provide a verifiable and sustainable supply foundation for global customers.

How GMP Is Applied in Daily Manufacturing

We view GMP as an operational framework rather than a final audit requirement.Raw materials are verified and batch-recorded before entering production

Raw materials are verified and batch-recorded before entering production

Critical process steps are defined with repeatable operating parameters

Manufacturing and quality functions are separated to reduce bias

Production records are used for analysis, not just archiving

This process-driven approach improves consistency and predictability.

Process Design Focused on Consistency

In Amygdalin production, consistency is prioritized over short-term optimization.

By standardizing process pathways and maintaining controlled parameter ranges, we minimize batch variation and support regulated applications.

Fixed process routes with controlled changes

Parameter adjustments undergo internal evaluation

Long-term batch data retained for trend analysis

This supports consistent performance across long-term supply.

Quality Control as Decision Support

Quality control serves as a basis for production decisions, not just pass/fail judgment.

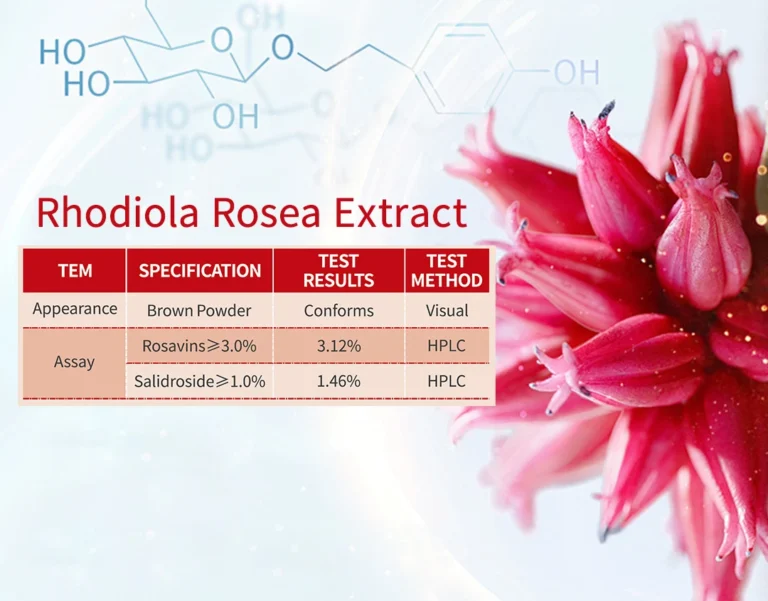

Analytical methods such as HPLC and UV are used for process monitoring

Test results support process adjustment and trend evaluation

Deviations can be traced back to specific process steps

Quality functions operate independently from production

This structure enables continuous improvement rather than reactive correction.

Regulatory Support for Global Markets

We recognize that regulatory support is as important as the product itself in global B2B operations.

Complete production and quality documentation available

Spport for audits and technical communication

Documentation aligned with actual manufacturing practices

Facilitates internal compliance and registration processes

This verifiable compliance capability supports long-term partnerships.

Stable Manufacturing as the Ultimate Goal of GMP

For us, the ultimate goal of GMP is not passing inspections, but achieving stable, repeatable, and sustainable manufacturing.

This stability reduces uncertainty and enhances supply security for customers engaged in long-term procurement and product development.

About Us

Chengde Trend Biotechnology Co., Ltd. is a GMP-compliant Amygdalin manufacturer focused on standardized production and long-term supply stability. With process management, quality consistency, and regulatory awareness at our core, we serve global customers with structured requirements for natural ingredients.