Introduction to Chengde Shiitake Base in Hebei and the Processing of Shiitake Extract with 30% Polysaccharide

Rooted in the ecological fertile land of Chengde and deeply engaged in the characteristic edible fungi industry in Chengde adheres to the core development philosophy of “Building the Foundation with Ecological Cultivation and Empowering Development with Precision Processing”. It has built an integrated whole-industry-chain system that covers both high-quality shiitake cultivation and core component extraction.

By leveraging the unique natural conditions of Chengde, the company has established a standardized shiitake base, focusing on the production of high-specification products such as shiitake extract with 30% polysaccharide content. With stringent quality control and professional processing capabilities, it contributes to the development of the health industry and demonstrates the responsibility of local enterprises.

I. Ecological Fertile Land: Chengde Standardized Shiitake Cultivation Base

Nestled in the hinterland of the Yanshan Mountains, Chengde features a temperate continental monsoon climate, boasting distinct four seasons, humid air, and significant temperature differences between day and night. These climatic conditions effectively promote the growth of shiitake mycelium and the accumulation of nutrients. Meanwhile, the region is endowed with loose and fertile soil, far from industrial pollution, and enjoys clean air and water quality, which together provide a natural edge for the green and ecological growth of shiitake mushrooms. Our shiitake cultivation base is located right here, built in strict compliance with standardized cultivation norms. It adopts a facility – based greenhouse cultivation model, balancing natural light with scientific regulation to create a stable and suitable environment of temperature, light, water, and air for the growth of shiitake mushrooms.

Adhering to the concept of ecological cultivation, the base refrains from using harmful inputs such as chemical pesticides, chemical fertilizers, and hormones throughout the entire cultivation process. It selects high – quality strains and uses natural substrates like decomposed sawdust and cottonseed hulls as culture media. Through green prevention and control measures including artificial refined management and physical pest control, the base ensures the natural and healthy growth of shiitake mushrooms. Additionally, a sound traceability system has been established at the base, which records in detail key links such as strain cultivation, inoculation, growth management, and harvesting time of shiitake mushrooms. This guarantees the purity, safety, and stable quality of shiitake raw materials from the source, laying a solid raw material foundation for the subsequent extraction of high – purity polysaccharides.

II. Precision Processing:

Craftsmanship Forges the Core Product of Shiitake Extract with 30% Polysaccharide Content

Leveraging the high-quality shiitake raw materials produced by the base, the factory focuses on its core business—the R&D and production of shiitake extract containing 30% polysaccharide. It is equipped with a Class 100,000 clean production workshop, internationally advanced extraction and separation equipment, as well as precision testing instruments. A professional team consisting of senior R&D personnel and technical backbones has been assembled.

Strictly complying with the processing standards for food additives and health product raw materials, as well as the requirements of the GMP quality management system, the factory realizes refined and standardized control over the entire process from raw material screening to finished product delivery, ensuring that the polysaccharide content in the product accurately and stably meets the core target of 30%.

The core processing flow is rigorous and controllable, with the key steps as follows:

1. Precise Raw Material Screening : Freshly harvested shiitake mushrooms are promptly transported to the factory. Damaged, rotten, deteriorated, and worm-eaten ones are manually removed, and high-quality shiitake mushrooms with thick caps, neat gills and sufficient accumulation of active ingredients are selected, thus controlling product quality from the source.

2. Low-temperature Drying Pretreatment : The low-temperature vacuum drying process is adopted to precisely control the drying temperature and duration. This process efficiently removes moisture from shiitake mushrooms while maximizing the retention of active ingredients such as shiitake polysaccharides, avoiding the degradation and loss of ingredients caused by high temperatures.

3. Ultra-fine Grinding and Extraction : Dried shiitake mushrooms are subjected to ultra-fine grinding to increase the raw material contact area. Then, the modern ultrasonic-assisted water extraction technology is applied. By intelligently regulating the extraction temperature, duration and solid-liquid ratio, the efficient dissolution and extraction of shiitake polysaccharides are achieved, improving the extraction efficiency and purity.

4. Purification and Concentration : The extract undergoes multi-stage filtration and purification to remove impurities such as proteins and cellulose. Subsequently, the extract is concentrated via a low-temperature concentration process to further increase the concentration of shiitake polysaccharides, ensuring the product purity meets the standards.

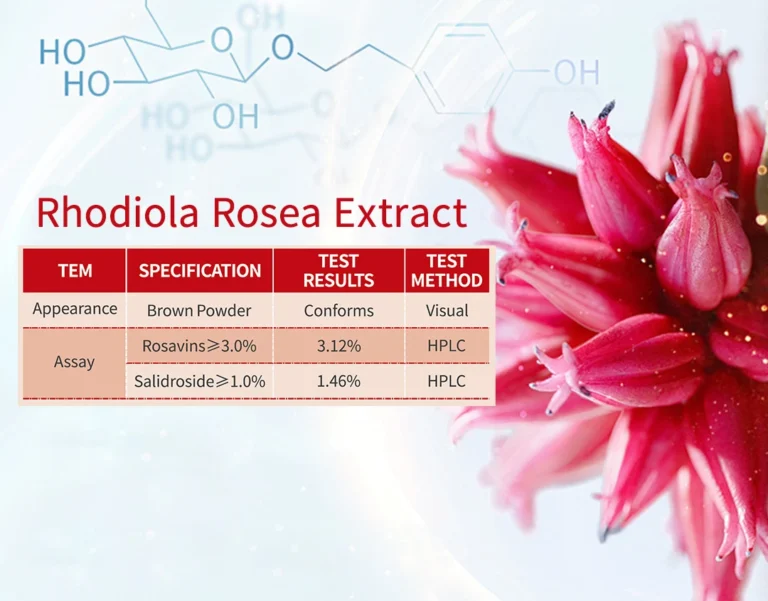

5. Stringent Quality Control and Testing : The quality control team uses precision testing equipment such as high-performance liquid chromatography (HPLC) to conduct tests on multiple key indicators of each batch of products, including shiitake polysaccharide content, heavy metals, microorganisms and moisture content. This ensures the products comply with relevant national standards and the enterprise’s internal control requirements, and non-conforming products are strictly prohibited from leaving the factory.

6. Aseptic Packaging and Warehousing : Qualified products are transferred to the aseptic packaging workshop, where environment-friendly packaging materials with sealing, moisture-proof and light-proof properties are used. Each package is labeled with product specifications (30% polysaccharide content), batch number and traceability code. The packaged products are then stored in a dedicated constant temperature and humidity warehouse to ensure long-term stable product quality.

III. Local Commitment: Synergistic Development of Ecology and Industry

As a local enterprise in Chengde, we have always adhered to the development philosophy of “Ecology First, Quality Foremost”, and deeply integrated the development of the shiitake industry with ecological protection and rural vitalization.

The standardized operation of the shiitake base and the processing production of the factory have adopted the “Enterprise + Base + Farmer” cooperation model, driving surrounding farmers to participate in shiitake cultivation, raw material harvesting and sorting, broadening the channels for farmers to increase their income, and injecting vitality into local economic development. Meanwhile, the base adopts an ecological cultivation model, effectively practicing the concept of green agricultural development and safeguarding the ecological environment of Chengde.

In the future, Chengde Tianrunda Biotechnology Co., Ltd. will continue to rely on Chengde’s unique natural endowments, keep deepening its efforts in the field of shiitake extract, continuously optimize cultivation and processing technologies, and enhance R&D and innovation capabilities. We will empower the development of multiple sectors such as health products, food and cosmetics with higher-quality shiitake extract products containing 30% polysaccharide. At the same time, we will uphold the responsibility of a local enterprise, promote the synergistic win-win of ecological, economic and social benefits, and contribute to the high-quality development of Chengde’s characteristic industries.